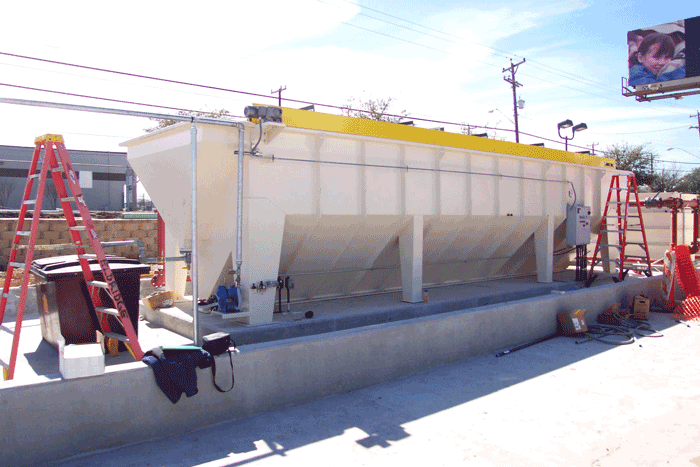

API Oil Water Separator

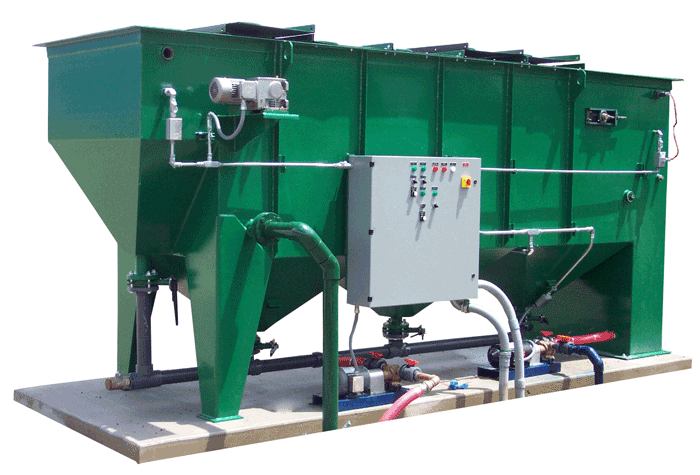

Industrial Coalescing Oil Water Separator(OWS)

Picking the right API Oil Water Separator

Products removed: motor oils, fuels (vehicle/jet), fuel oils, hydraulic fluids, immiscible machining oils, lube oil, transmission fluid, bunker c, DNAPLs, LNAPLs, vegetable based oils, crude, air compressor lube & other many hydrocarbon based derivatives (BTEX etc..). Model sizing is based on the oil/fuel specific gravity, droplet size removal desired and other parameters of the waste stream.

- Integral oil reservoir

- Forkliftable skid, lifting lugs

- Flat bottom

- Sectional cover w/zinc hardware

- Carbon or Stainless steel construction

- Adjustable water weir

- Expandable effluent chamber

- Epoxy internal/external coatings

- 150 mg/L performance

PERFORMANCE

Solids (TSS) 40 -100 mg/L

Influent concentration basis:

Oils 1250 mg/L or less influent loading

TSS 500 mg/L or less influent loading

While the API421 guide typically provides for an effluent discharge performance of 100 mg/L, 150 micron oil droplets it is possible with a properly designed API to provide performance down to 50 mg/L but not less. These performance figures are typically independent of the influent concentrations and are calculated as if in an ideal environment, which is not accurate to real-world experience. Actual performance is highly dependent on the type of waste entering the separator and the conditions within the separator.

OIL WATER SEPARATOR THEORY

V = (2gr²)(d1-d2)/9µ

where

V = velocity of rise (cm sec-¹),

g = acceleration of gravity (cm sec-²),

r = “equivalent” radius of particle (cm),

dl = density of particle (g cm -³),

d2 = density of medium (g cm-³), and

µ = viscosity of medium (dyne sec cm-²).

With the use of our Flow-Thru media oil only need rise a short distance before encountering the oleophilic, coalescing media plates inside the separation chamber as opposed to rising a great distance in gravity separation. Upon impinging on the plates the oils coalesce (gather) into larger droplets until the droplet buoyancy is sufficient to pull away from the media and rise to the water’s surface. The design will meet particular design criteria as indicated below:

The hydraulic distribution of the influent flow must assure full usage of the cross-sectional area of the media to fully utilize the plate pack’s surface area.

o Flow control and direction must be determined to prevent hydraulic short circuiting around, under or over the media pack.

o A laminar flow condition must be maintained (Reynolds “Re” number less than 500) in order to assist droplets to rise. Per the American Petroleum Institute’s (API) Publication 421 of February 1990.

o Horizontal flow through velocities in the separator must not exceed 3 feet per minute or 15 times the rate of rise of the droplets whichever is smaller.

o The media containment chamber design, plate design/angle and spacing sufficient to facilitate removal of accumulating solids. Plates are to be smooth surfaced and angled at 60 deg.

The first and oldest type is gravity or conventional separation, simple separation via gravity (density differential between two immiscible liquids leads to one of them rising above the other). This design, when designed properly (or even improperly) provides a certain tank length, width and depth that provides a wide, quiet spot in the pipeline to give oils time to rise. This design (also known as an API separator) generally provides a discharge oil concentration of 100 ppm based on a 150 micron droplet size. The API type design relies on a large water volume. This correlates to a tank size that can be 5 times the size of an equally sized coalescing separator.

The coalescing design is known by many names i.e. parallel plate, corrugated plate, slant rib coalescer so on and so forth. However, the concept, operation and design are generally the same. The coalescing concept is based on having a large surface area in contact with the waste stream (coalescing plates). The more surface area provided, the more enhanced the separation process will typically be. By using the coalescing media, the size of the tank is reduced and a higher performance is attained than by gravity separation. SkimOil Flow-Thru coalescing design provides a discharge oil concentration of 10 PPM or less with an oil droplet size of 30 or as small as a 20 micron oil droplet.

APPLICATIONS: OWS

Contaminated ground water treatment for removal of gasoline, diesel, JP, jet fuels,

LNAPL, DNAPL, motor oils, kerosene, fuel oils and more.

Refineries

Removal of crudes, gasoline, diesel fuel, motor oils, transmission fluids,

hydraulic fluids, jet fuels, aircraft fuels from refining processes.

Vehicle Wash Racks

Removal of gasoline, diesel fuel, motor oils, transmission fluids, hydraulic fluids, jet fuels, aircraft fuels and lubricants when washing jets, cars, trucks, heavy equipment, railroad locomotives and equipment.

Military Wash Racks

Field equipment, jet wash, tracked equipment wash uses for typical fuels and oils removal. Complete treatment systems are offered. (Also see VEW systems)

Industrial Process Water

Hydraulic fluids, machining coolant/cutting fluid tramp oil removal, compressor condensate, machined parts rinse water.

Steel Mills

Rolling mill hydraulic oil/water extraction, compressor condensate, stormwater runoff, drain water.

Stormwater Treatment

Parking lot runoff, railroad re-fueling depot runoff, gas station runoff, bridge runoff.

Shipping Ballast & bilge water treatment.

Off-loading of water to shore based treatment system, bunker & diesel fuels removal.

Tank Farms

Fuel, oil storage tank farms for removal of water from tank bottoms. Stationary and mobile systems are offered.

Petro-Chemical

Refineries, chemical compounding companies, hydrocarbon based chemical bases such as cumene and other materials.

Power Generation

Generator lube oils, hydraulic oils, fuels. Stationary & mobile systems offered.

Heat Treating

Heat treating facility oily wash solution can be continuously treated.