Waste Water Evaporator

ShoreVAP–Gas Fired Waste Water Evaporator

This massive reduction in the volume of liquids requiring disposal not only slashes disposal costs, but also economizes by reducing storage area requirements, labor and time for handling, and frequency of disposals. All ShoreVAP water evaporators have been designed to operate simply and efficiently, and are constructed of quality materials and equipment to assure trouble-free operation and long-life service, as demonstrated by the thousands of systems in service. Installation is easy.

Make your place the NO DISCHARGE ZONE! The SHOREVAP wastewater evaporator ZERO LIQUID DISCHARGE With this simple, rugged device, all your waste waters automatically heated to boiling and turned into vapor that is then vented to atmosphere through a blower-assisted stack. Venting is easy. Water vapor is not considered a pollutant. DOES IT AFFECT YOU? You bet! The FEDS are coming!

List of No Discharge Zones(NDZ) by State

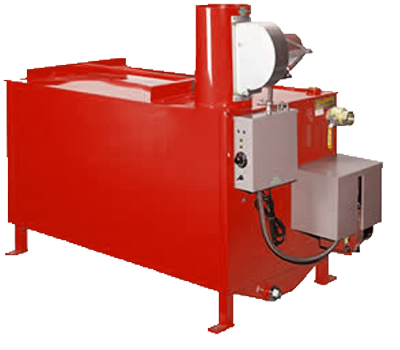

This is NOT a Hubble Telescope—-it’s a simple THUG of a wastewater evaporator. Well proven Simple construction for over 20 years simple controls, simple operation and the waste water is simply gone. Also available in electric powered…with no emissions.

Gas Fired ShoreVAP Specifications

Auto-Fill Mode: 12 Gallons/ Hour (45 Liters)

Auto-Fill Mode: 18 Gallons/ Hour (68 Liters)

Auto-Fill Mode: 40 Gallons/ Hour (151 Liters)

16 Gauge Painted Exterior

16 Gauge Painted Exterior

16 Gauge Painted Exterior

200,000 BTU;

81" x 6-1/2" Heat Exchanger

285,000 BTU;

141" x 6-1/2" Heat Exchanger

400,000 BTU;

381" x 6-1/2" Heat Exchanger

43" L x 45" W x 54" H (with Pump/AFS)

73" L x 45" W x 54" H (with Pump/AFS)

73" L x 45" W x 77" H (with Pump/AFS)

7" to 14" W.C.

120 VAC/13 Amp/1 Phase

7" to 14" W.C.

120 VAC/13 Amp/1 Phase

7" to 14" W.C.

120 VAC/13 Amp/1 Phase

2" Drain with Plug

2" Drain with Plug

2" Drain with Plug

Labor & Corrosion excluded

Labor & Corrosion excluded

Labor & Corrosion excluded

Your evaporation rate may be different depending on your waste stream and environmental conditions.

Evaporation rates will be less with electric over natural gas.

positive airflow sensing, and thermally protected blowers.

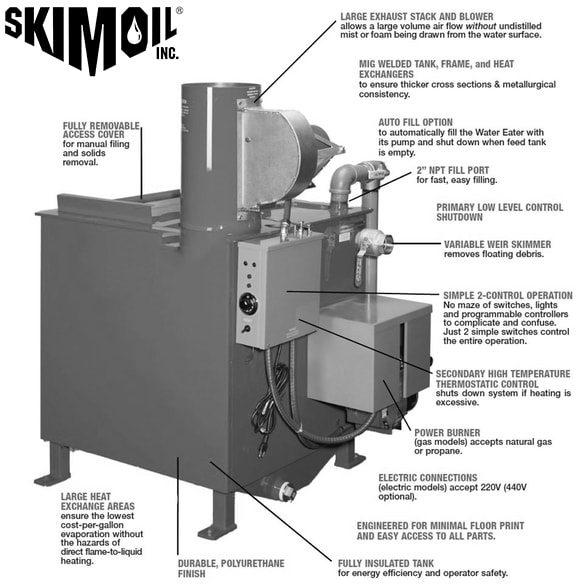

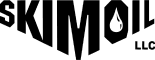

These units use large 6 1/2” diameter, Schedule 10, immersion tube heat exchangers which are located well above a funneled floor to allow significant collection and concentration of sludge and solids without covering the burner tube. The oversized heat exchanger surface area is extremely efficient, allowing for a more accurate water distillilation while avoiding water misting.

The obstruction-free funneled floor and perimeter mounted burner tubes simplify clean out. Our exclusive variable weir skimmer is standard on all units.

Industries Served & Applications:

Machine Coolant Water, Parts Washer Water, Hot Tank Water, Stem Cleaner Water, Dye Penetrants, Floor Scrubber Water, Water Base Paint Washup, Alkaline Cleaners, Stencil Cleaner, Wire Draw Compounds, Phosphatizing Compounds, Paint Spray Water, Compressor Concentrates, Mop Waters, Rinse Waters, Die Cast Solutions, Water Based Inks, Tumbling and Vibratory Fluids, Photographic Solutions.

FEATURES: