Waste Water & Air Compressor Condensate Evaporator

The Condensate Evaporator

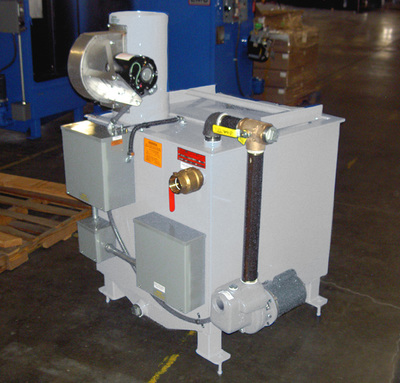

Air Compressor Condensate OWS Evaporator

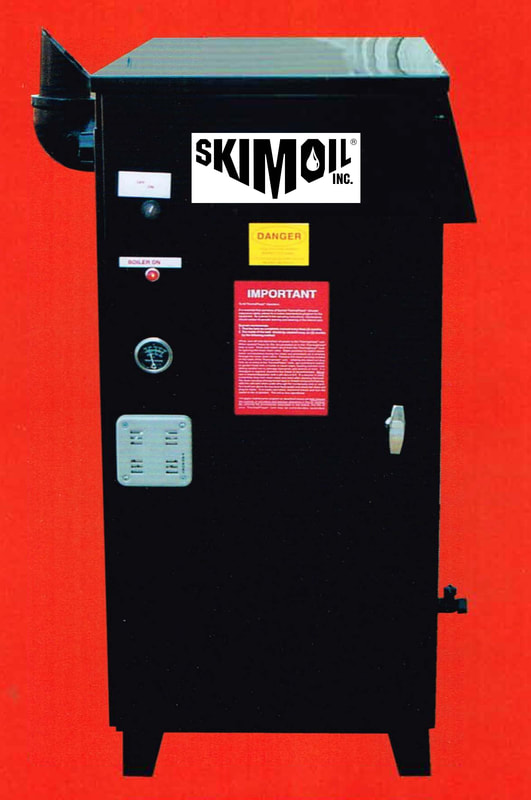

ConEVAP is a positive action solution to the problem of safely disposing of air compressor condensate.

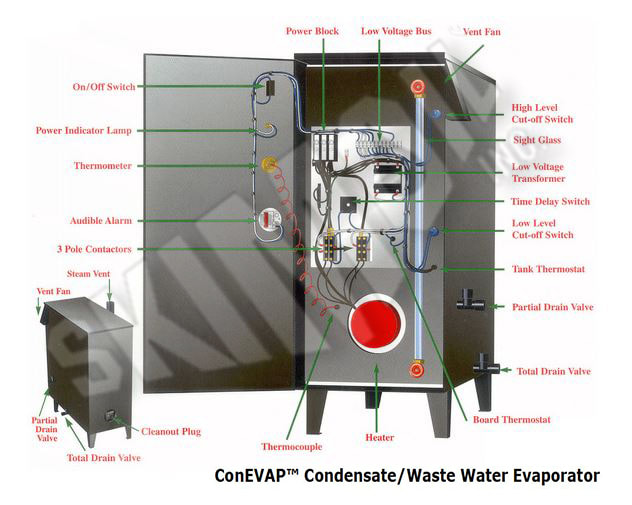

The ConEVAP oil water separator is a thermostatically controlled, electrically heated evaporation unit that separates air compressor condensate from spent compressor lubricant. The condensate water leaves the unit as atmospheric steam and the lubricant is periodically drained from the unit.

ConEVAP offers an economical alternative to having your condensate hauled away by a licensed disposal company. The ConEVAP™ heating elements and control mechanisms utilize off-the-shelf components which simplifies spare parts.

CLICK TO SEE THE BROCHURE HERE!!!

Lbs/Hr - Gals/Hr

H x L x W

Special Design Features:

There is a 4 inch clean out plug in the back of the unit for convenient cleaning of the internal chamber and heating element every six months. There is also a sight glass to allow the operator to monitor performance of the unit and decide when to drain the unit.

A thermometer is provided to monitor the operating temperature and determine when the lubricant has cooled to a safe temperature for draining. There are two thermostats for overheating protection and two drain valves for partial and total draining on the unit. The ConEVAP oil water separator utilizes high efficiency insulation to conserve energy and provide a safe physical environment. Over 90 percent of the energy input is utilized to convert condensate to steam. ConEVAP provides you with a safe, positive solution to a persistent problem.

#1 Tough rugged simple bare bones, Bubba Proof system with simple controls the BilgeVAP

#2 sophisticated with lots of controls and even pretty —the ConEVAP

No discharge zone? No problem!